Overview

Rockwell Automation's Studio 5000 is a cutting-edge PLC (Programmable Logic Controller) programming software that has established itself as a premier tool in the control and automation sector.

With an emphasis on user-friendliness and efficiency, this software empowers engineers to develop, implement, and maintain PLC programs with ease, catering to a diverse range of applications from simple machine control to complex process automation.

This in-depth analysis of Studio 5000 will cover a wide range of topics, such as its programming abilities, user interface, hardware integration with Rockwell Automation, and Rockwell Automation's ongoing support and updates. The goal is to show you why this tool is so important for control and automation specialists.

1. User Interface and Navigation

Studio 5000 has a well-thought-out, user-friendly, and adaptable interface.

A project explorer that offers quick access to several components such as controllers, tasks, programmes, and routines greets users when they activate the software.

Navigating through different sections of the software is seamless, thanks to the tab-based interface, allowing users to work on multiple projects simultaneously.

Moreover, the software’s workspace is highly customizable, allowing users to arrange windows, tools, and toolbars according to their preferences, enhancing productivity during complex projects.

2. Project Organization and Management

Engineers may organise their projects more easily with Studio 5000's effective project management system.

Users can create multiple programs and routines, which can be grouped logically within a project.

The programme also facilitates version control, which makes it easier for team members to collaborate and helps keep a history of project revisions.

3. Programming and Language Support

Numerous programming languages, such as ladder logic, structured text, function block diagrams (FBDs), and sequential function charts (SFCs), are available in the software.

Because of its adaptability, control and automation experts may select the best programming technique for a given application, which makes code creation and maintenance more efficient.

The online/offline programming capability allows users to make modifications and debug PLC code even when the PLC is running in real-time.

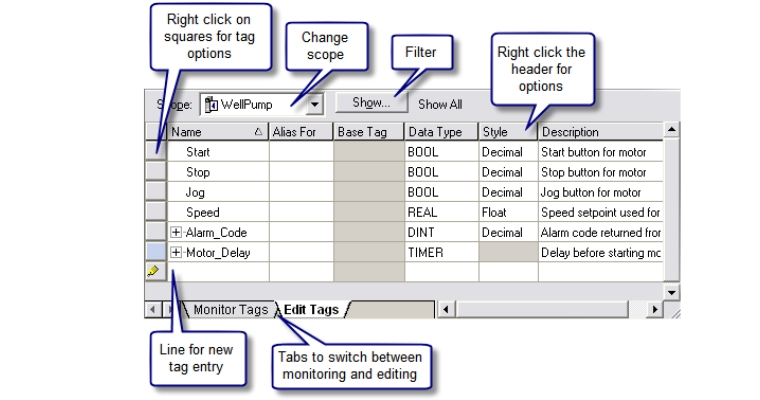

4. Tag-Based Programming

The tag-based programming method in Studio 5000 is one of its best features. The programme uses descriptive tags for variables and input/output (I/O) points instead of standard addresses.

This method reduces mistakes during system integration, improves readability, and streamlines programme organization.

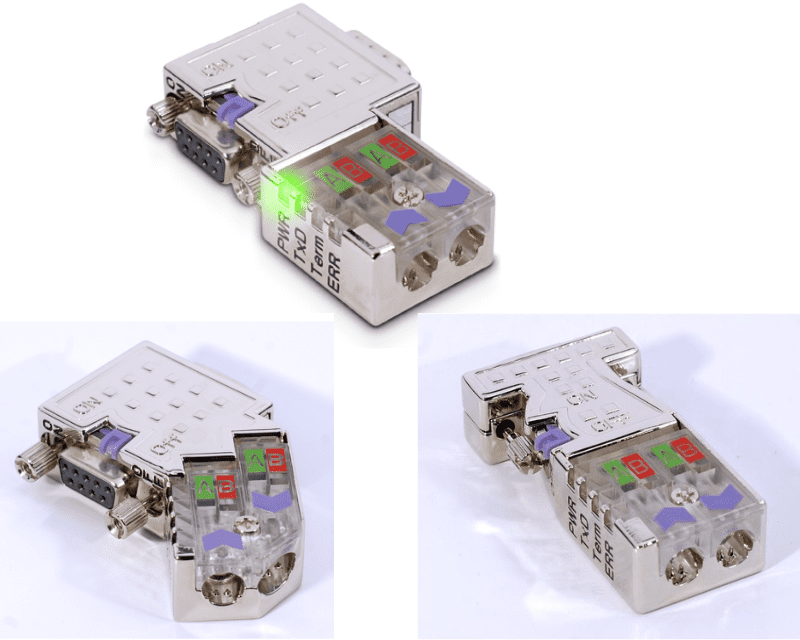

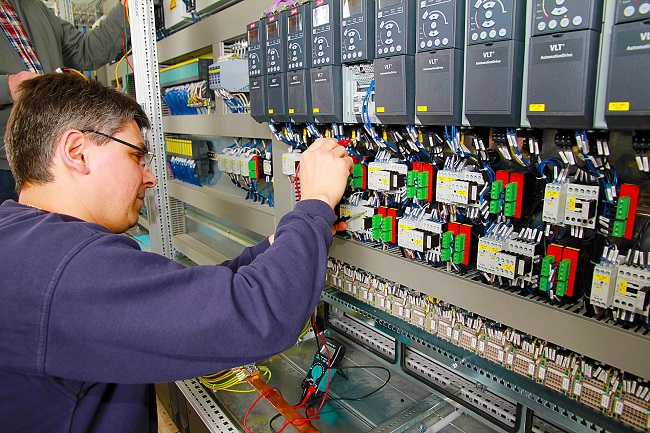

5. Device Integration and Configuration

Smooth integration is provided by Studio 5000 with a range of Rockwell Automation hardware platforms, including as Allen-Bradley HMIs and PLCs.

The programme drastically cuts down on the amount of time needed to set up hardware setups by offering a large library of pre-configured devices.

Furthermore, it supports communication protocols such as EtherNet/IP, Modbus, and OPC-UA, enabling smooth communication between different devices and third-party systems.

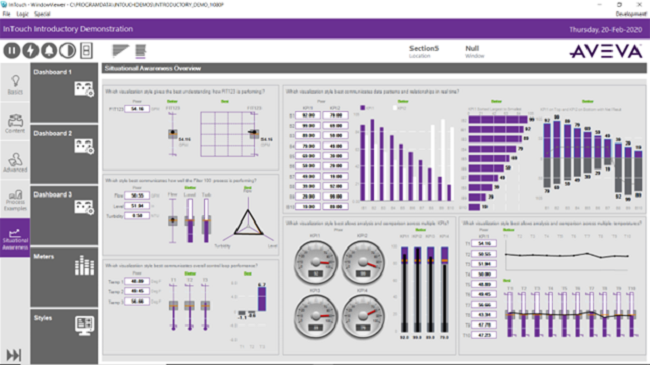

6. Diagnostic and Troubleshooting Tools

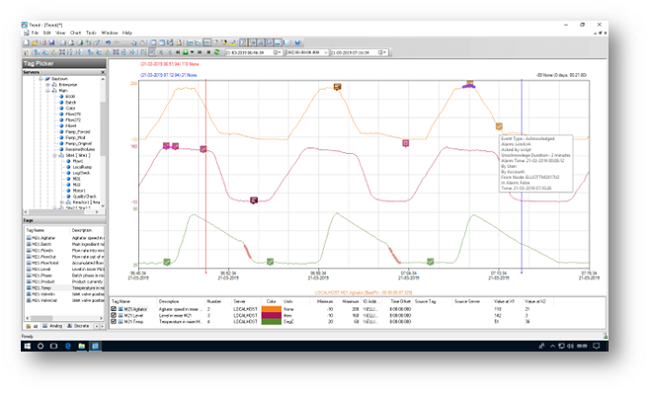

The software comes equipped with powerful diagnostic tools, aiding control and automation engineers in identifying and resolving issues efficiently.

Real-time data visualisation is made possible by online trending and monitoring tools, which provide customers the ability to analyse PLC performance and decide on system optimisation.

Additionally, the software offers comprehensive error logging and diagnostics, simplifying troubleshooting during runtime.

7. Support and Community

Customer assistance from Rockwell Automation is well-known, and Studio 5000 customers may take use of an abundance of resources, including as official documentation, a knowledge base, online forums, and user communities.

The active user community fosters collaboration, knowledge sharing, and problem-solving among professionals, making it easier to overcome challenges and learn from each other’s experiences.

8. Performance and Reliability

Performance and dependability are excellent features of Rockwell Automation Studio 5000 PLC Programming Software.

Because of the software's responsiveness and speedy compilation times, engineers can test and implement modifications to their PLC programmes more effectively.

The seamless integration with Rockwell Automation hardware further enhances the overall performance, as it allows for optimized communication and coordination between the PLC and other devices.

Moreover, the software’s stability and robustness are essential for critical automation applications, where downtime is not an option.

9. Continuous Improvement and Updates

Rockwell Automation is dedicated to making all of its products, including Studio 5000, better every day.

To fix errors, provide new features, and guarantee compatibility with the most recent firmware and hardware versions, software updates and patches are frequently published.

The software is kept current and relevant by this commitment to improvement, which allows it to adjust to the changing demands of the control and automation sector.

Furthermore, Studio 5000 is a dynamic and user-driven platform since it values user feedback and frequently incorporates community feature requests into next releases.

10. Scalability and Flexibility

Scalability and versatility are two of Studio 5000 PLC Programming Software's main advantages.

The programme can handle a wide range of automation projects with varying sizes and levels of complexity, whether it's a tiny isolated system or a huge distributed control architecture.

Engineers can effortlessly scale up or down Studio 5000 as project needs change, which makes it a great option for both straightforward and complex automation systems.

Additionally, engineers may select the devices that best fit their needs thanks to the software's interoperability with a variety of Rockwell Automation hardware platforms, giving them the flexibility needed to satisfy a variety of project requirements.

11. Safety and Security

Security and safety are top priorities in the control and automation sector.

Because Studio 5000 takes these factors seriously, it provides strong features that guarantee the integrity and safety of the automation systems.

For essential applications, the software facilitates the construction of redundant setups, enabling high availability and fault tolerance.

To further guard against unwanted access and manipulation of PLC programmes, Studio 5000 has sophisticated security features including role-based access control, user identification, and authorization.

Control and automation experts may rest easy knowing that their systems are protected from possible attacks and vulnerabilities thanks to these security measures.

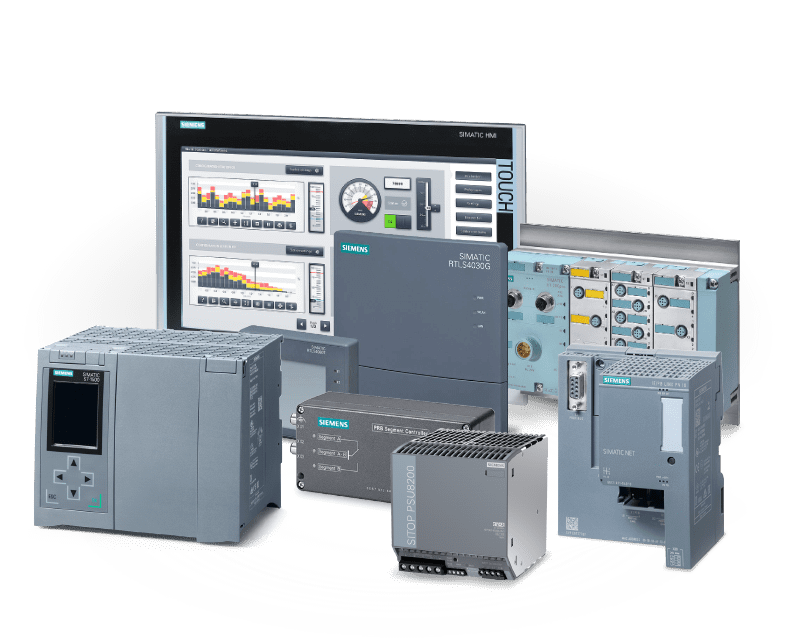

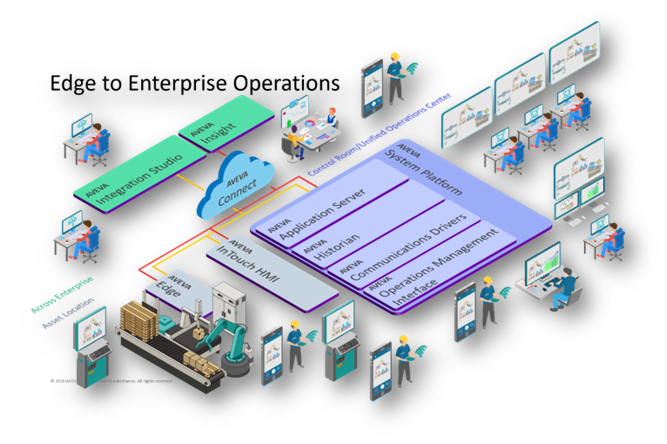

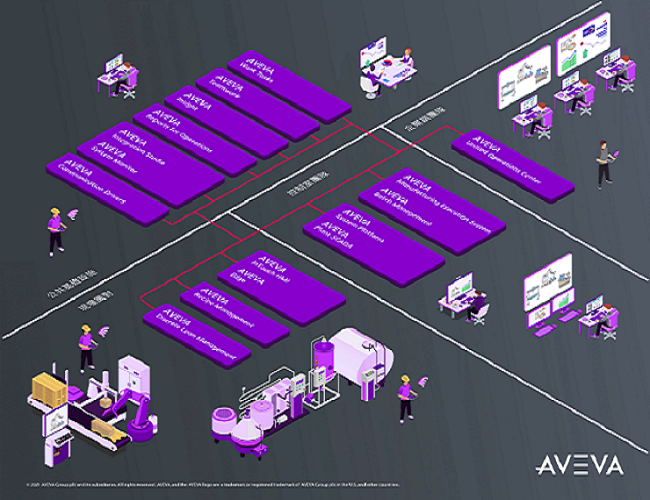

12. Integration with Ecosystem

The larger ecosystem of tools and solutions offered by Rockwell Automation may be effectively integrated with the Studio 5000 PLC Programming Software.

It is simple to integrate with FactoryTalk Historian for data collecting and analysis, FactoryTalk AssetCentre for centralised project version control and change management, and FactoryTalk View for HMI development.

The whole automation project lifecycle from design and development to commissioning and maintenances streamlined by this thorough integration.

The tight-knit integration between various Rockwell Automation software products results in a cohesive and unified automation ecosystem, enhancing efficiency, reducing engineering effort, and enabling a holistic approach to control and automation.

13. Support for Industry Standards

The Studio 5000 PLC Programming Software is engineered to conform to many industry standards, guaranteeing compatibility and interoperability with other control and automation systems and software.

The widely used worldwide standard for PLC programming languages, IEC 61131-3, is supported by it, allowing engineers to write code that complies with accepted industry standards.

Furthermore, by supporting OPC-UA, the software makes it easier to integrate it with software and other automation devices from other suppliers, fostering an environment that is open and interoperable.

Control and automation engineers may create systems that are not just dependable and efficient, but also readily maintained and future-proof by following these principles while using Studio 5000.

In summary, because of its easy-to-use interface, wide support for languages, tag-based programming, and smooth hardware connection, Studio 5000 PLC Programming Software is a great tool for control and automation experts. The software’s diagnostic and troubleshooting tools, coupled with excellent support and an active user community, make it a valuable asset for professionals in the field. Its high performance, reliability, and commitment to continuous improvement cement Studio 5000’s position as a top choice for developing complex automation systems. While there may be a learning curve for beginners, the availability of training resources ensures that users can quickly become proficient and harness the full potential of Studio 5000 in their automation projects.

We are Asteam Techno Solutions Pvt Ltd: the go-to company for industrial automation products. We make a contribution to the circular economy by providing all industrial automation products for businesses and factories and also providing service work for them. We provide automation solutions with reputed brands including Allen Bradley, Mitsubishi, Phoenix Contact, Siemens, Schneider, Moxa, VIPA and more. Currently our staff members are serve a growing number of national and international customers each day.