Human-Machine Interfaces (HMIs) are graphical user interfaces that enable people to communicate with machines or other systems. HMIs simplify the control and monitoring of many processes for users by converting intricate machine operations into interactive features and graphics. These interfaces are frequently used by operators in industrial settings to monitor production lines, control equipment, and guarantee flawless functioning. HMIs not only enhance productivity, security, and decision-making, but they also provide data in an understandable and user-friendly way.

Graphical User Interfaces (GUIs) and HMIs are not the same thing; GUIs are frequently used in HMIs for visualization purposes.

HMIs are useful in the following industrial settings:

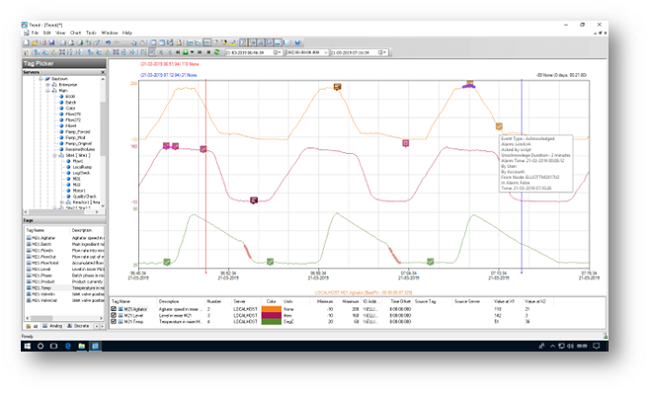

- Visually display data

- Track production time, trends, and tags

- Oversee KPIs

- Monitor machine inputs and outputs

HMI is used in industrial applications as well as consumer electronics, automotive systems, and smart home devices. Examples of how people interact with HMIs in daily life are infotainment systems in cars, control panels for appliances, and touchscreens on smartphones. HMIs are now more responsive and user-friendly because to advancements in gesture detection, voice commands, and touchscreen technology. These advancements demonstrate the rising significance of HMI in contemporary technology, improving user experience and paving the way for smarter, more interconnected settings.

Human-Machine Interfaces (HMIs) Hardware and software

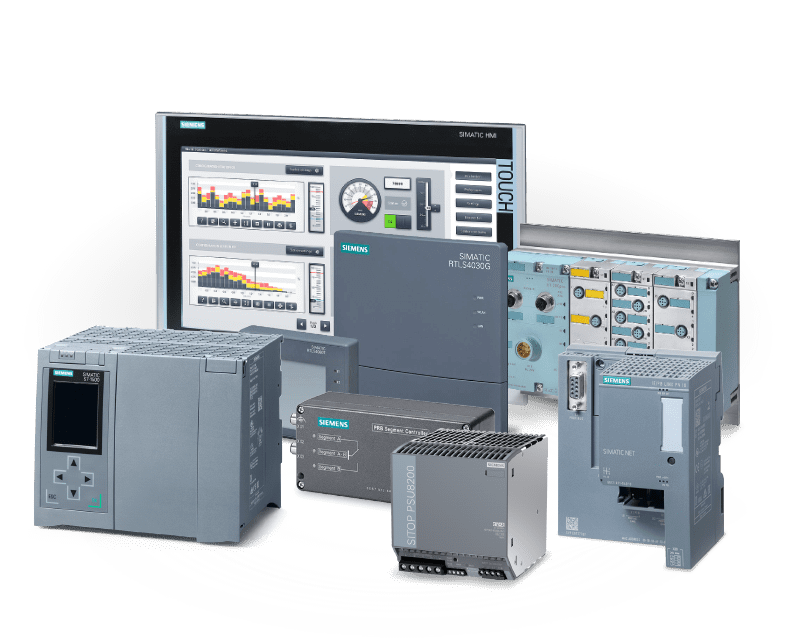

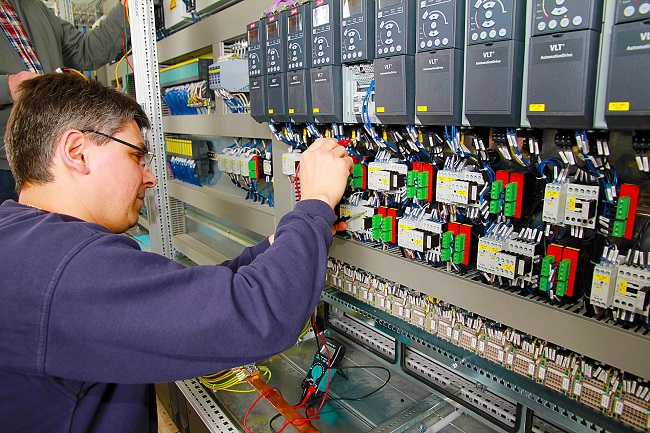

Software for human-machine interfaces (HMIs) offers an easy-to-use graphical user interface together with input/output controls to assist in monitoring and controlling complex industrial machinery. Wearables, mobile devices, desktop computers, and HMI hardware can all have HMI software installed.

How does HMI software work?

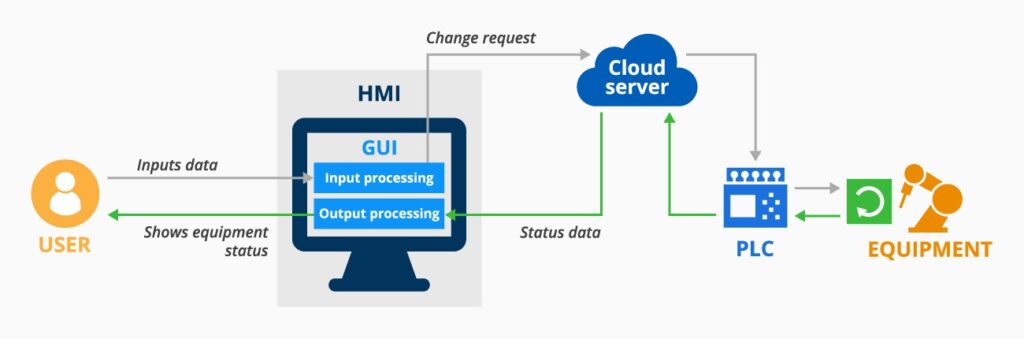

A Programmable Logic Controller (PLC) system is used by the majority of industrial machinery to regulate and automate certain activities. PLC systems and HMI devices work together to generate output actions in the machine when an input on the HMI device is modified.

For example, a conveyor belt's direction and speed may be controlled by a PLC, and the operator may be able to remotely change the speed through the use of HMI software. In order to facilitate data collecting or to take pictures and send them to the HMI software, the PLC system may also make use of sensors and cameras. This would provide the operator more supervisory control.

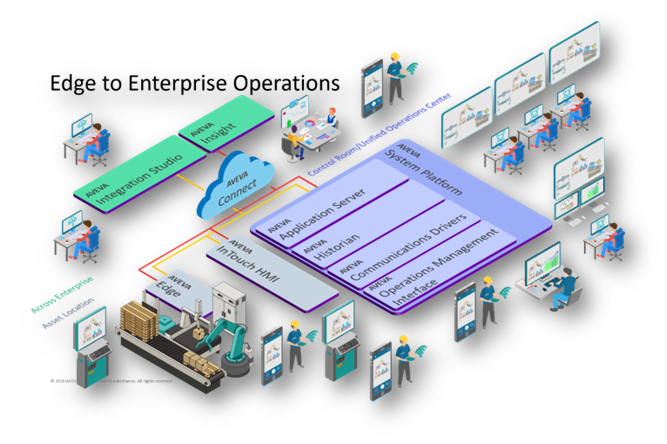

Instead of using a direct connected connection, the majority of contemporary Human Machine Interfaces and PLC systems interact via a cloud server and wireless internet. Typically, a touch screen device is used to show the HMI software dashboard.

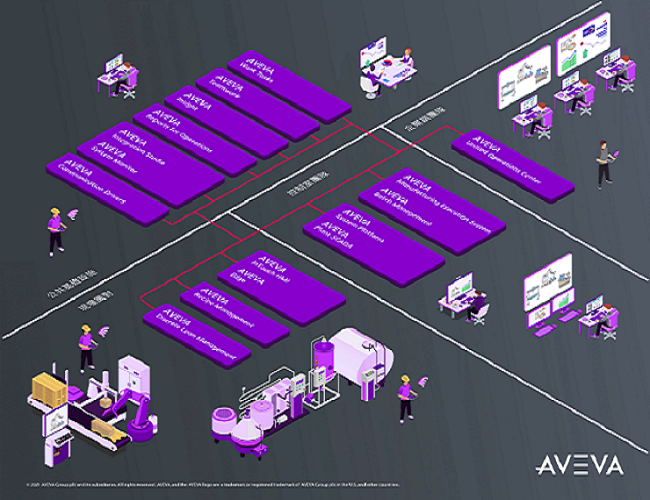

Examples of HMI Software

- Wonderware by AVEVA

- Ignition by Inductive Automation

- WinCC by Siemens

- FactoryTalk View by Rockwell Automation

Key Features of HMI Software

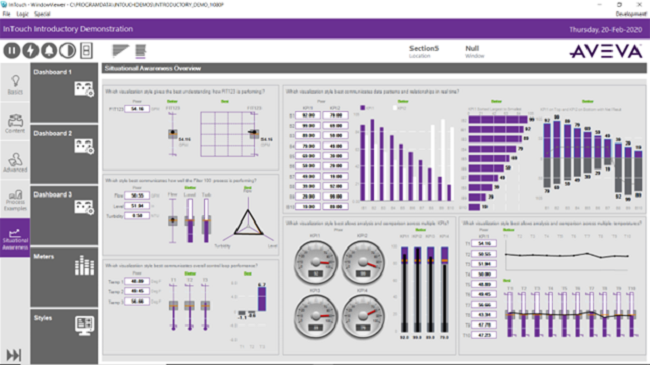

Real-Time Data Monitoring:

- Live data visualization through graphs, charts, and gauges.

- Alerts and notifications for important occurrences in real-time.

- Data logging for reporting and historical analysis.

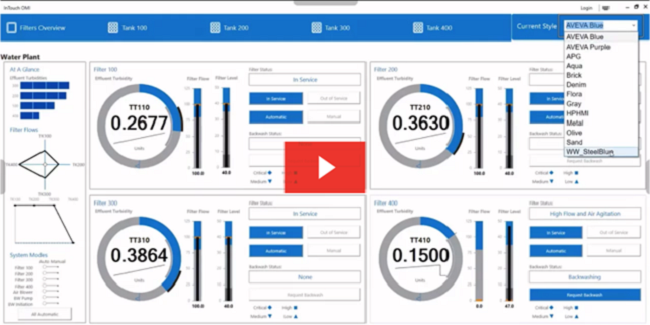

Scalability and Flexibility:

- Support for various devices and screen resolutions.

- The capacity to interface with many different kinds of software and hardware.

- Modular architecture allows for easy upgrades and scalability.

Integration with Other Systems:

- Compatibility with SCADA (Supervisory Control and Data Acquisition) systems.

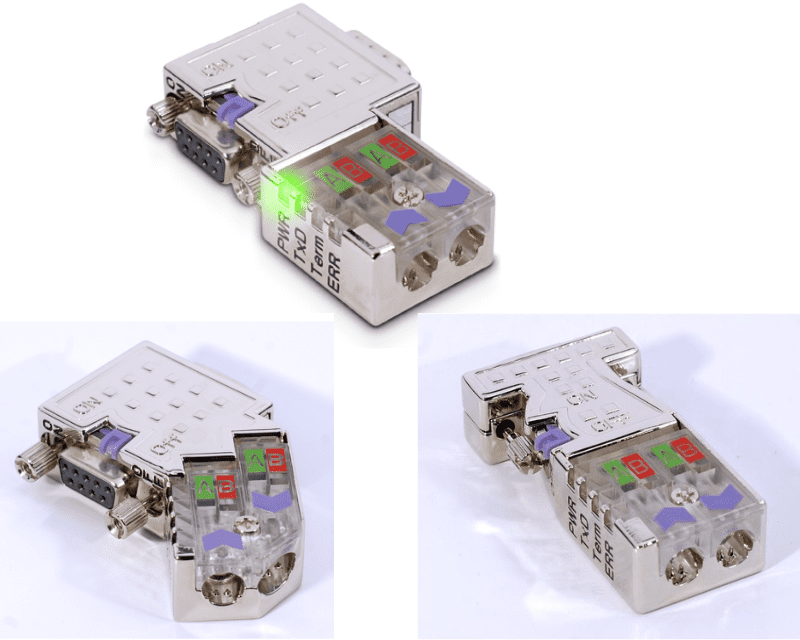

- Support for various communication protocols (e.g., OPC, Modbus, MQTT).

- APIs for integration with ERP, MES, and other enterprise systems.

Remote Access and Mobility:

- Web-based interfaces for remote monitoring and control.

- Support for tablets and smartphones with mobile apps.

- VPN and secure remote access options.

Data Analysis and Reporting:

- Built-in analytics tools for data interpretation.

- Customizable reporting templates and automated report generation.

- Export options for different formats (e.g., PDF, Excel).

Alarms and Event Management:

- Configurable alarm thresholds and prioritization.

- Alarm acknowledgement and escalation procedures.

- Event history tracking and analysis.

Multilingual Support:

- Multiple language support is provided to accommodate users worldwide.

- Easy localization and translation of the interface.

Applications of HMI Programming

HMIs are widely used in any industry, here are some of their applications:

Food processing:

HMIs provide operators with real-time visibility into various stages of food processing, such as mixing, cooking, cooling, and packaging. Operators can monitor critical parameters like temperature, pressure, humidity, and flow rates, ensuring consistent product quality and safety.

Manufacturing of pharmaceuticals:

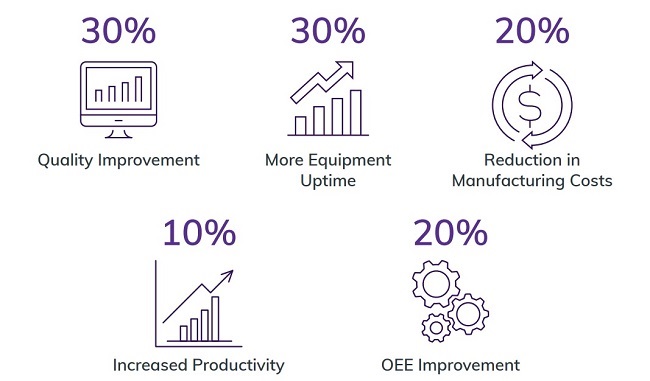

In the manufacturing sector, HMIs are crucial for the operation and control of machinery and production lines. Advanced HMI systems enable operators to monitor processes, adjust parameters, and diagnose issues in real time. For instance, in automated factories, HMIs are used to interface with Programmable Logic Controllers (PLCs), allowing operators to control and optimize production processes from a central location. The integration of HMI with Industrial Internet of Things (IIoT) devices has further enhanced data collection and analysis, leading to improved decision-making and predictive maintenance. This not only reduces downtime but also increases productivity and efficiency.

Building Automation:

HMIs are used to control and monitor systems within buildings, such as heating, ventilation, air conditioning (HVAC), lighting, and security systems. They provide a centralized interface for building managers to monitor and adjust parameters as needed.

Consumer Electronics:

Devices like smartphones, tablets, and smart home systems utilize HMIs to provide intuitive interfaces for users. Touchscreens and graphical user interfaces (GUIs) simplify interaction and enhance user experience.

Energy Management:

In power plants and renewable energy installations, HMIs help operators monitor energy production, manage distribution networks, and optimize resource utilization. They provide real-time data on energy consumption and grid performance.

Transportation:

In transportation systems like trains, planes, and automobiles, HMIs provide critical information to operators and passengers. They display navigation data, speed, fuel levels, and other vital information, enhancing safety and operational efficiency.

HMI is essential to contemporary production since it acts as a conduit between an automated system and a human operator. It is necessary to increase productivity, boost security, and simplify troubleshooting. An HMI's effectiveness can be significantly impacted by its design, with layout, colours, and graphics being important components.

With more complex and user-friendly interfaces predicted as a result of technological breakthroughs, the future of HMI in manufacturing seems bright. Technological advancements in fields like augmented reality, mobile technology, and artificial intelligence are about to completely change how operators communicate with industrial systems. Therefore, every company looking to maximize its manufacturing processes and maintain its competitiveness in the market must comprehend and utilize HMI.

If you are looking for any Industrial automation software solutions reach us at contact@asteamtechno.com for Support | Solution | Inquiry | Upgradation | Modification

i need to learn hmi software program to do electronics projects for industrial applications

Excellent breakdown of complex topics. Very helpful!