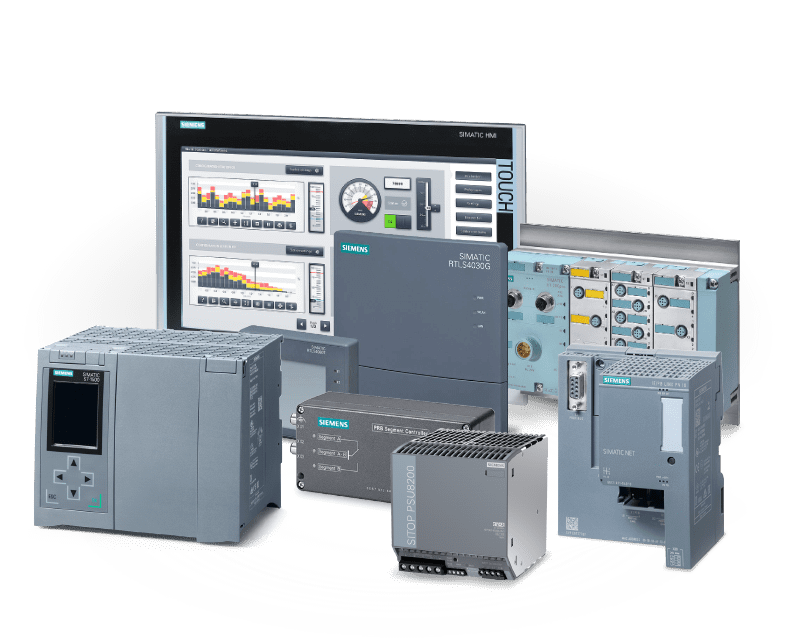

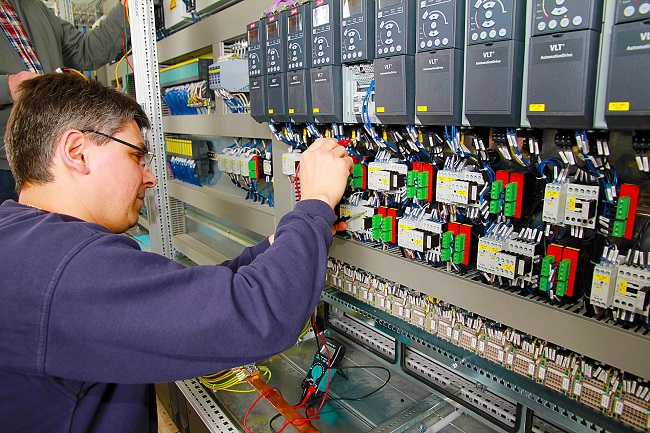

An industrial Ethernet switch is a network device designed to connect multiple Ethernet-enabled devices within an industrial environment. Unlike standard commercial Ethernet switches, industrial Ethernet switches are built to withstand harsh conditions such as extreme temperatures, vibrations, and electrical interference. They facilitate the smooth transfer of data between devices like programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and actuators

Network switches made specifically for use in challenging industrial settings are called industrial Ethernet switches. Industrial-grade network equipment is needed for oil rigs, railroads, factories, and other applications with a wide range of temperature, humidity, vibration, electrical noise, and physical contamination (oil, water sprays).

Because industrial networking solutions and manufacturing automation settings have strict, predictable network requirements, industrial automation experts have adapted Ethernet to produce industrial Ethernet switches.

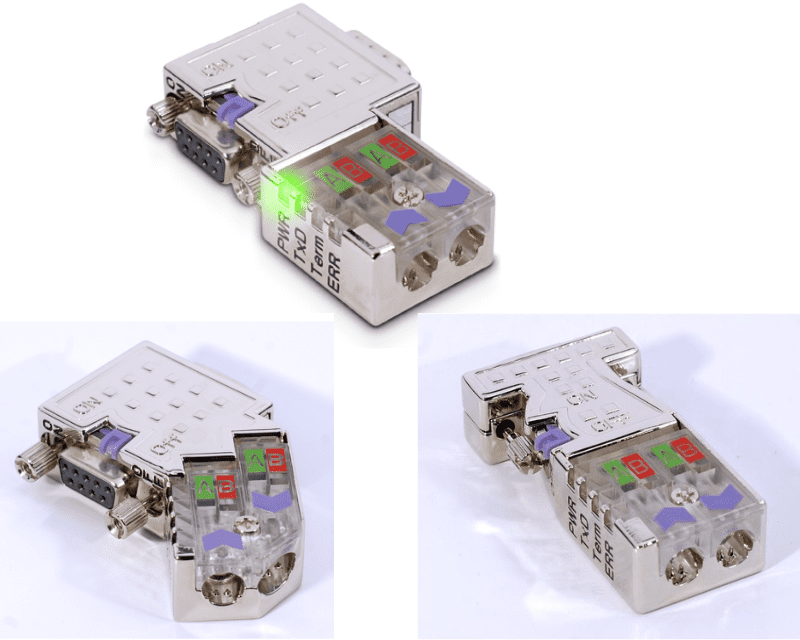

Main Features of Phoenix Contact 1000 Industrial Ethernet Switches

1085039: A small Ethernet switch with five RJ45 ports that can each transmit data at speeds of up to 100 Mbps. The switch incorporates autocrossing capability and automatically determines the best data transfer speeds. Furthermore, it has Quality of Service (QoS) features.

1085256: Streamlined Ethernet switch with eight RJ45 connections that can accommodate 10/100 Mbps data speeds. The switch has Quality of Service (QoS) features, auto crossing for hassle-free setup, and automatic determination of the appropriate data transfer speed.

1085255: Stylish Ethernet switch with sixtееn RJ45 ports, each of which is universally set to transfer data at 10/100 Mbps. Quality of Service (QoS) capabilities are included, an autocrossing mechanism for seamless connectivity is included, and the switch automatically determines the ideal data transfer speed.

Key Features of Industrial Ethernet Switches

- Wide Operating Temperature Range: These switches are designed to function reliably over a broad temperature range, often from -40°C to 75°C or even higher. This makes them suitable for extreme environments such as manufacturing floors, outdoor installations, and remote locations.

- Enhanced EMI/RFI Protection: Industrial environments can be rife with electromagnetic interference (EMI) and radio frequency interference (RFI) from various machinery. Industrial Ethernet switches are built with robust EMI/RFI shielding to ensure uninterrupted data transmission.

- Long Distance Communication: Industrial Ethernet switches often support fibre optic connections, enabling long-distance communication between devices. This is particularly useful in large industrial plants or outdoor installations where devices are spread out over vast areas.

- Redundancy and Reliability: Industrial Ethernet switches often support redundancy features like Rapid Spanning Tree Protocol (RSTP), Media Redundancy Protocol (MRP), and Ethernet Ring Protection Switching (ERPS). These features help maintain network connectivity in case of a link or device failure, ensuring minimal downtime.

- Power over Ethernet (PoE) Support: Many industrial Ethernet switches provide PoE capabilities, allowing them to deliver power to connected devices such as IP cameras, wireless access points, and VoIP phones directly through Ethernet cables. This reduces the need for additional power infrastructure.

- Advanced Management Features: These switches have advanced management capabilities like VLAN support, Quality of Service (QoS), and SNMP for monitoring and configuring the network. These features are crucial for optimizing network performance and security.

Advantages of Industrial Ethernet Switches

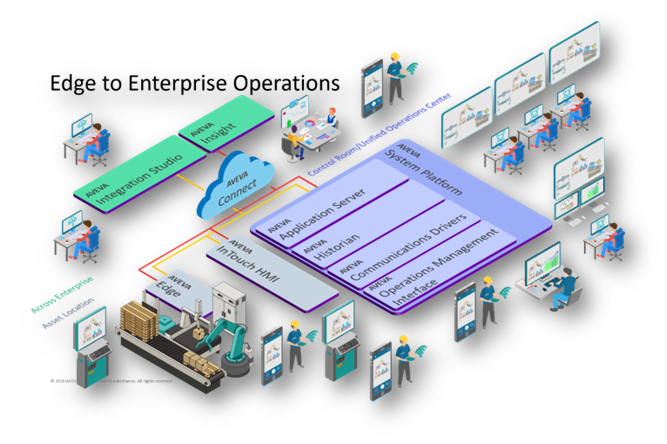

In the modern landscape of industrial automation and smart manufacturing, connectivity is key. Industrial Ethernet switches play a pivotal role in ensuring robust, reliable, and high-speed communication within industrial networks.

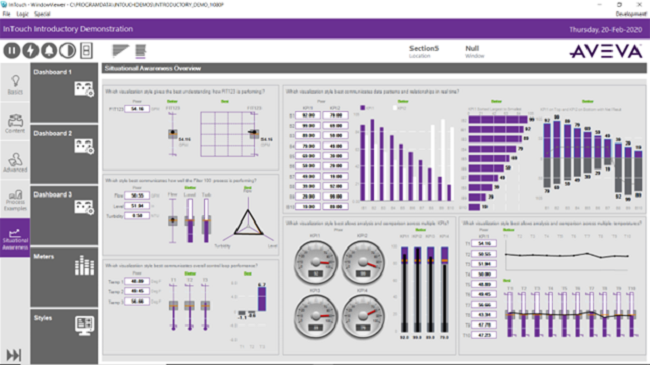

- Superior Network Performance: High-speed data transmission is critical in industrial settings where real-time communication is essential. Industrial Ethernet switches support high bandwidths and low latency, ensuring that data packets are transmitted swiftly and efficiently. This performance is vital for automation control systems, where delays can result in significant operational inefficiencies.

- Scalability: As industrial operations expand, so does the need for scalable network solutions. Industrial Ethernet switches offer a scalable architecture, allowing for easy integration of additional devices and network segments. This flexibility supports the growth and adaptation of industrial networks without the need for extensive reconfiguration or investment in new infrastructure.

- Advanced Security Features: Security is a paramount concern in industrial networks due to the potential impact of cyber threats on critical infrastructure. Industrial Ethernet switches have advanced security features such as VLANs (Virtual Local Area Networks), MAC address filtering, and secure management interfaces. These features help protect the network from unauthorized access and ensure that sensitive data remains secure.

- Ease of Integration with Legacy Systems: Many industrial environments operate with legacy systems that require seamless integration with modern network solutions. Industrial Ethernet switches are designed to be compatible with a wide range of industrial protocols and standards, facilitating smooth integration with existing infrastructure. This compatibility ensures that organizations can upgrade their networks without the need for complete overhauls.

- Simplified Network Management: Managing a complex industrial network can be a daunting task. Industrial Ethernet switches offer simplified network management through features such as remote monitoring, diagnostic tools, and centralized management platforms. These capabilities allow network administrators to monitor network performance, identify issues, and implement changes quickly and efficiently.

- Support for Industrial Protocols: Industrial Ethernet switches support various industrial communication protocols such as EtherNet/IP, Modbus TCP, and PROFINET. This support ensures compatibility with various industrial devices and systems, enabling cohesive and efficient communication across the entire network.

Applications of Industrial Ethernet Switches

- Manufacturing and Automation: Manufacturing floors are bustling with activity, where seamless communication between machines, sensors, and control systems is crucial. Phoenix Contact Ethernet switches facilitate real-time data transfer and ensure uninterrupted connectivity. They are designed to withstand harsh industrial environments, withstanding extreme temperatures, vibrations, and electrical noise. By providing reliable network infrastructure, these switches help optimise production processes, reduce downtime, and ensure the smooth operation of automated systems.

- Energy Sector: In the energy sector, particularly in power generation and distribution, network reliability is paramount. Phoenix Contact Ethernet switches are used to create resilient and scalable network infrastructures that connect various components like substations, transformers, and control centres. These switches support high data throughput and advanced network management features, making them ideal for handling the complex requirements of smart grids and renewable energy systems.

- Industrial Internet of Things (IIoT): The term "Internet of Things" (IoT) refers to the technology Ethernet Switch used when Industrial Ethernet Switches link devices that are also online. IoT may entail linking widely dispersed physical devices to the internet to gather and share data for control and monitoring. The term "industrial network solution" (IIot) or occasionally "IoT industrial solutions" is broadened when the environment includes difficult working conditions (such as oil or water spray) or extremely high temperatures.

- Oil and Gas Industry: The oil and gas industry operates in some of the most challenging environments, from offshore rigs to remote pipelines. Phoenix Contact Ethernet switches are engineered to provide reliable network connectivity in these extreme conditions. They support the integration of various monitoring and control systems, ensuring real-time data flow for efficient and safe operations.

- Building Automation: Building automation systems (BAS) require a seamless communication network to manage lighting, HVAC, security, and other systems efficiently. Phoenix Contact Ethernet switches offer the flexibility and reliability needed to support complex BAS. They enable centralized control and monitoring, leading to improved energy efficiency and occupant comfort.

Industrial Ethernet switches are integral to the success of modern industrial networks. Their robustness, performance, scalability, and security features make them an indispensable component of any industrial automation strategy. By investing in industrial Ethernet switches, organizations can ensure reliable and efficient network operations, driving innovation and competitiveness in the industrial sector.

Insightful and well-written. Thanks for sharing!