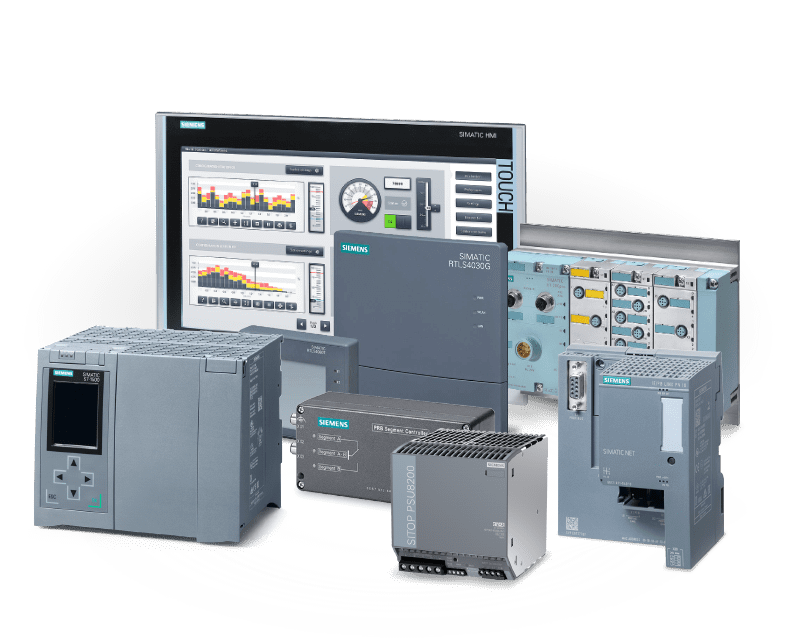

An industrial computer control system known as a PROGRAMMABLE LOGIC CONTROLLER (PLC) continually checks the condition of input devices and decides how to regulate the output devices based on a customised programme.

This kind of control system may yield significant improvements for almost any kind of manufacturing line, machinery, or process. The capacity to alter and duplicate the operation or process while gathering and transmitting crucial data, however, is the primary advantage of utilising a PLC.

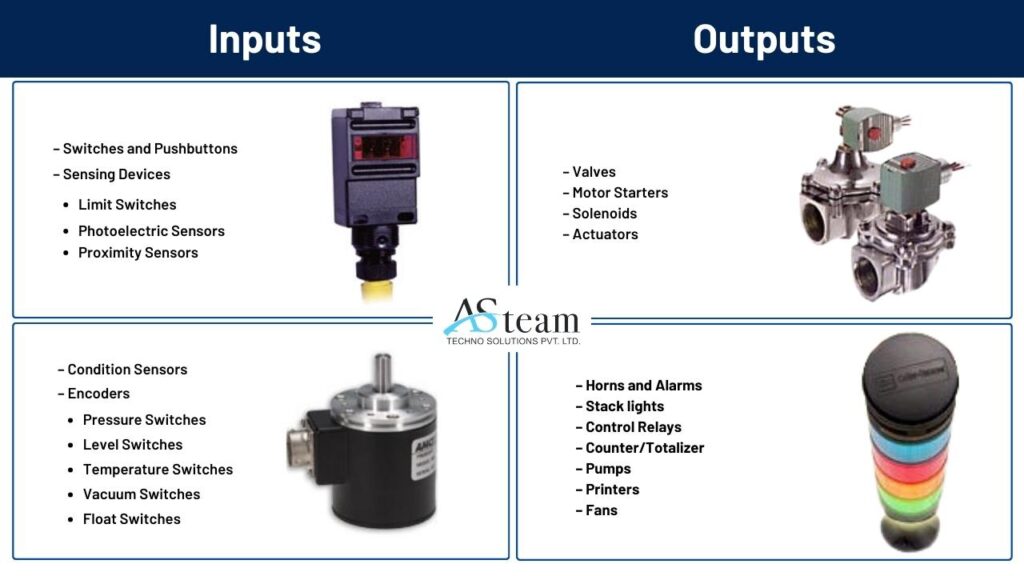

Modularity is another benefit of a PLC system. To best fit your application, you can combine several types of input and output devices.

History of PLCs

The first Programmable Logic Controllers were designed and developed by Modicon as a relay re-placer for GM and Landis.

- With the help of these controllers, it was no longer necessary to rewire or add hardware for every new logic arrangement.

- The new approach reduced the amount of cabinet space needed to house the logic while significantly increasing the usefulness of the controls.

- Dick Morley created the first PLC, the type 084, in 1969.

- Michael Greenberg built the first commercially successful PLC, the 184, which was originally released in 1973.

What is inside a PLCs?

The CPU, or central processing unit, has an internal programme that instructs the PLC on how to carry out the following tasks:

- Put the User's Programmes' Control Instructions into action. Since this programme is kept in "nonvolatile" memory, it won't be lost in the event of a power outage.

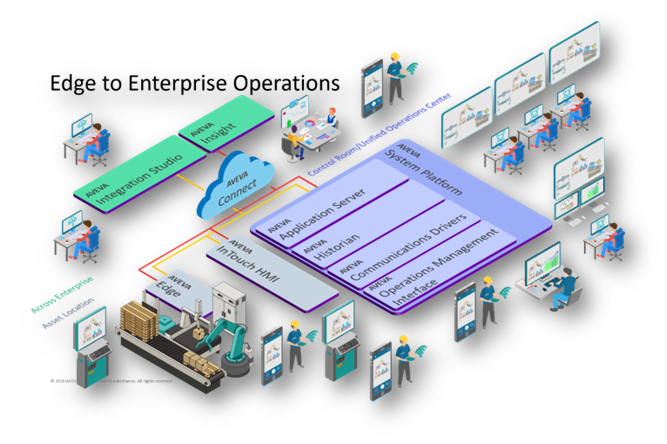

- Interact with other devices: PLCs, networking, I/O devices, and programming devices are examples of other devices with which to communicate.

- Carry out housekeeping tasks including internal diagnostics, communications, etc.

How does a PLC operate?

All PLCs operate in four fundamental steps: input scan, programme scan, output scan, and housekeeping. These acts are looped back and forth repeatedly.

Four Steps in The PLC Operations

1) Input Scan

- Evaluates each input device linked to the PLC to determine its current state

2) Program Scan

- Executes the user created program logic

3) Output Scan

- Activates or deactivates each output device that is attached to the PLC.

4) Housekeeping

- Internal diagnostics, programming terminal communications, and other tasks are included in this stage.

What programming language is used to program a PLC?

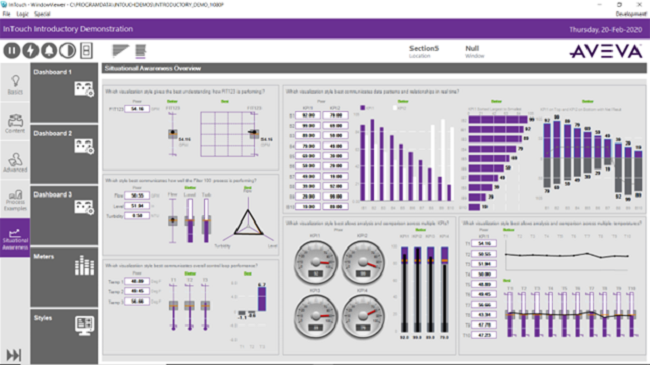

There are several PLC programming languages available besides Ladder Logic, which is the most often used one. A few of the languages used to programme PLCs are included in the table below.

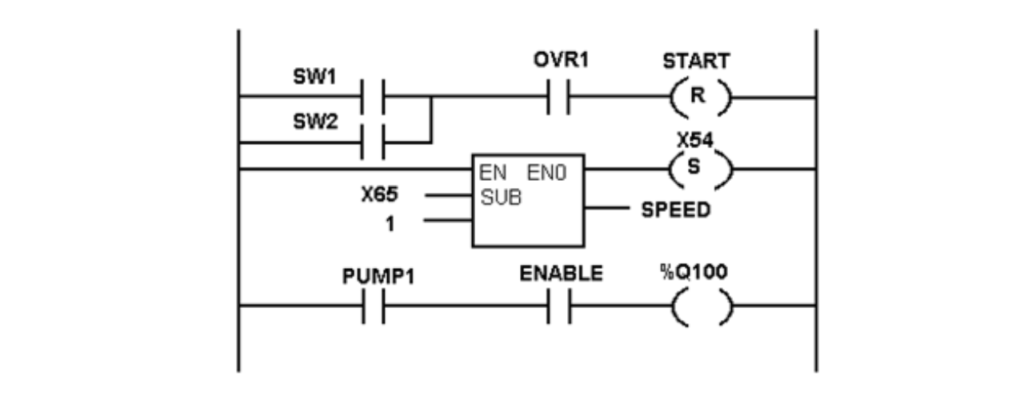

Chart of Ladders (LD) Graphical programming languages are used in traditional ladder logic. Ladder Logic programming was once limited to basic contacts that mimicked the opening and shutting of relays. However, it has since been expanded to incorporate math operations, timers, shift registers, counters, and timers.

Function Block Diagrams (FBDs) are reusable function blocks that are used to represent signal and data flows graphically. For explaining how the logic and algorithms of a control system are interconnected, FBD is quite helpful.

A high-level text language called Structured Text (ST) promotes organised programming. It supports a large number of standard functions and operators and has a language structure (syntax) that is quite similar to PASCAL. For instance,

If Speed1 > 100.0 then

Flow_Rate: = 50.0 + Offset_A1;

Else

Flow_Rate: = 100.0; Steam: = ON

End_If;

A low level "assembler like" language called Instruction List (IL) is based on comparable instructions list languages used in a variety of modern PLCs.

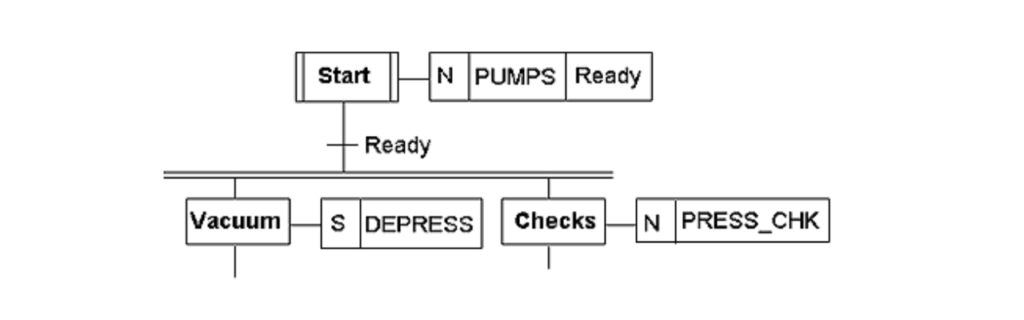

The Sequential Function Chart (SFC) is a highly organised programming tool for complicated control systems. Complete programme files serve as the fundamental building elements of an SFC programme, which is a summary of the control system. A programming language other than the ones listed above is used to produce each programme file. The SFC method divides complex, large-scale programming projects into smaller, easier-to-manage activities.

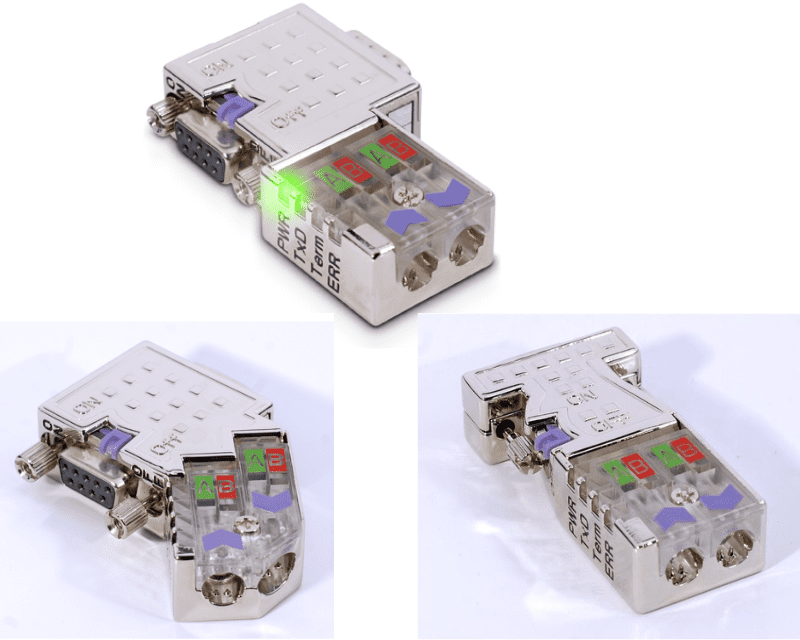

What are input/output devices?

In conclusion,

PLCs are essential to contemporary industrial automation because they provide a dependable and adaptable means of managing intricate procedures. By offering a strong foundation for automation and control, they have completely transformed the manufacturing sector and raised industrial operations' productivity, efficiency, and safety. for